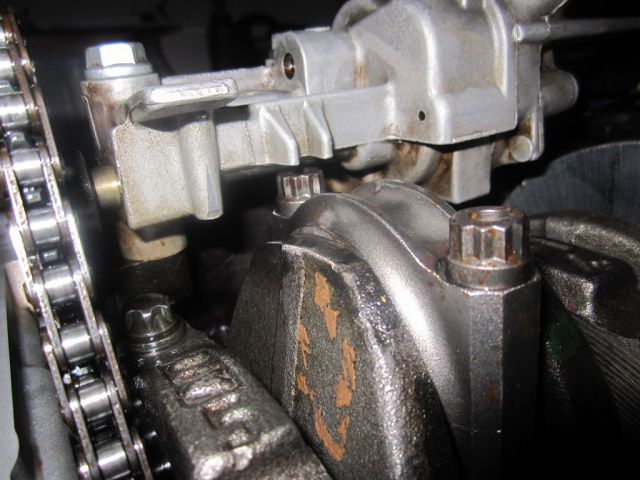

After assembling the engine I realised that ARP bolts on the conrod foul on the oil pump drive shaft (714 has chain driven pump).

That's how deep the hole is in the bolt centre

Because I don't want to cut into oil pump driveshaft for obvious reasons, I'm thinking about lowering the ARP bolt's head for a few mm. I just not sure how this affects bolt strength.

Are there any other uprated bolts with lower head available?

Results 1 to 10 of 11

-

21-05-2012, 22:14 #1

F7R 714, Woessner forged rods and ARP bolts problem

-

22-05-2012, 14:14 #2

Maybe it would be better if you could lower(on lathe ofcourse) bolt head from the thread side.

-

22-05-2012, 14:32 #3

Are the heads hitting the underneath or just those 2 fins on the side?

What are those fins,are they important,if not maybe consider removing them?

-

22-05-2012, 15:11 #4

its hitting the shaft cover itself, clearing the fins

that's a bit of a puzzler really. I wouldn't say trimming the bolts down from the top would affect their strength, but I don't really know, theres a lot of forces inside that engine acting on the big ends etc so it'd be hard to condone modifying them

is it the bolts or the rods that are the issue? have you seen if std bolts fit and if arp bolts fit with std rods?

-

22-05-2012, 15:15 #5Forum User

- Join Date

- Oct 2010

- Posts

- 304

I don't know how the chain driven pump works exactly so: is there a tensioner on the vhain? If not how much play do you have?

You could try to put some bushings between block and pump which gives some more room...

-

22-05-2012, 17:42 #6

Ok, just to write my conclusions to make this thread helpful if someone else will have the same problem in the future...

Making bolt shorter on the thread side makes no difference how high bolt head is. It would just affect clamping ability. It's possible to modify big end to make the bolt sit lower, but due to the design of Woessner rods, that's not a good idea, because there's not that much material you could take away without compromising rod strength. Originally Posted by dkrevs

Originally Posted by dkrevs

It's not hitting the shaft cover, that is the shaft. So decision between thinning the oil pump drive shaft or shaving the conrod bolt head is like choosing between being shot in the face or in the back of your head. Both options have equally bad outcome. Originally Posted by Coops

Originally Posted by Coops

But when I fitted original Renault bolt (6.90mm head height) it cleared the pump shaft with big gap. It's also just the near bolt, other bolt on the same conrod clears the shaft easily (ARP). Head height on ARP bolt is 10.00mm so it's much higher than original bolt. Forces act on the bolt head with angle of 45 degrees from bolt center line. That's why there can be a hole in the middle of the bolt, as that is essentially a dead material that just adds weight. So in theory by shaving the bolt down you could compromise it. But it's also true that heads are so big to have enough surface area to be able to take bigger tightentng torques compared to the OEM bolt.

I also contacted ARP factory in USA and they said I could shave the head down a bit as long as I will be careful not to heat up the bolt too much during the milling process. Also tightening the bolt should be done with more care, since there will be less surface area for the socket to transfer the torque to the bolt.

I will shave the bolt between 1-2mm, will have to do some precise measurements so I can take away as little as possible.

So remember... Woessner rods, F7R 714 and ARP bolts (not just ARP 2000, all their bolt designs have roughly the same bolt head) are a big no no, unless you are prepared to do some modifications...

Thanks for reading! :D

-

22-05-2012, 17:50 #7

Also forgot to mention that OEM rods are 2mm lower than Woessner rods, so ARP bolts would probably clear the pump with OEM conrods.

-

22-05-2012, 18:46 #8

That's how I meant:

If the manifacturer says that it's ok to remove the top of the bolt head a little, well probably then there is no easier option really.

-

22-05-2012, 23:01 #9

I would suggest that you use a linisher rather than a miller,less chance of catching and bending the bolt

-

23-05-2012, 01:08 #10Forum User

- Join Date

- Oct 2008

- Location

- www.519automotive.co.uk

- Posts

- 590

I would buy new bolts, but I've told you that

Similar Threads

-

BRAND NEW - F7R/F4R Wossner forged rods & ARP bolts

By Evogone in forum Items for SaleReplies: 1Last Post: 06-02-2013, 14:47 -

Forged pistons low comp and forged rods

By andyrg in forum WantedReplies: 1Last Post: 14-04-2011, 13:42 -

forged con rods for f7p or f7r for sale

By GTTURBO in forum Items for SaleReplies: 0Last Post: 04-06-2010, 08:15 -

Forged con-rods

By 16v_paddy in forum Performance/ECU TuningReplies: 9Last Post: 19-11-2008, 12:59 -

forged rods

By thelynx in forum EbayReplies: 3Last Post: 14-02-2007, 12:13

Reply With Quote

Reply With Quote