OK heres the deal, thinking of going another route, this engine was fully rebuilt no expense spared, it ran very very well for 5500 miles before its failed compltetely.

2 M6 bolts were sucked into cylinder #1, the engine locked when cranking over, so there is possible, head damage, valve damage, piston and bore damage, so this sale is conditional of the damage (or lack of), when the engine will be taken apart this saturday. ANyway heres the spec...

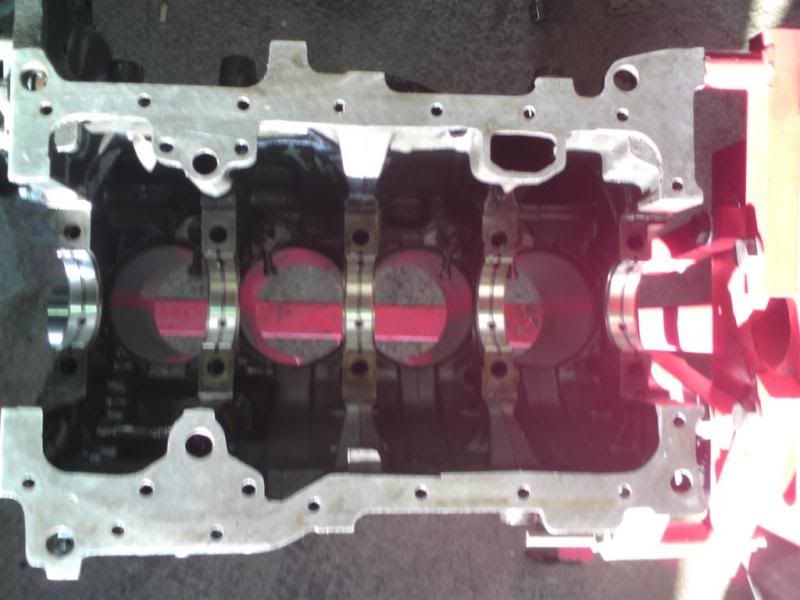

- Cylinder Block stripped down inspected and cleaned (inc Oil Jets)

- Oil pump stripped down, inspected and cleaned

NEW PARTS:

- All new bottom end gaskets and seals - £60

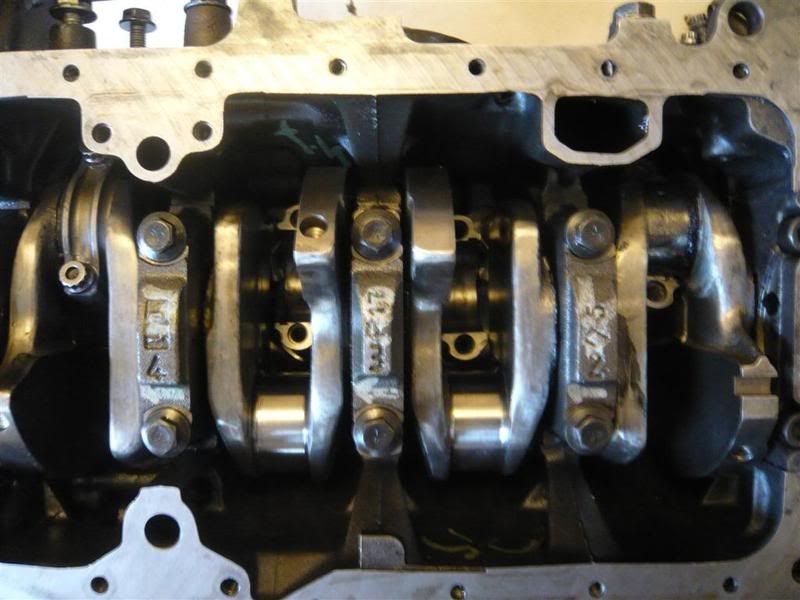

- ACL Main end bearings - £40

- Glyco big end bearings - £40

- Crank thrust washers - £30

- JE Proseal Piston Rings - £130

- Cylinder block hone - £60

- Cylinder block skimmed to match piston heighy- £60

- Piston Ring End Gapping - £150

JE Forged H/C Pistons 11.2:1 - ~£500

Forged Con Rods - ~£300

ARP Rod BOlts - £60

Other info..

It was built largely with the help from Craig @ AP-Developments.

Has a worked crankshaft, its been destressed (sharp edges have been smoothed), maybe balanced too?

Engine puffs and bloffs absolutely no smoke what so ever, and does not burn oil.

A few things to note, this block is an original ,its using all original size bearings and an original unground crankshaft.

When i put the pistons in, i bent 2 of the rings by accident, as a result i had a second set of brand new piston rings shipped over and fitted these. Because i only needed 2 oil scraper rings (minor), i have the other 16 new rings in the pack still so they can be used on a future rebuild.

The engine holds absolutey immaculate oil pressure. I can back this up, as i run with a mehcanical oil pressure gauge.

Cold idle 4 bar ish. When cold the engine will hill 5.5 bar from 2000rpm onwards, and maintain this to around 4000rpm where it shoots of upto 7bar+ (hence always carefully warmed up).

When fully up to temperature after a spritied drive, the engine will make 4.2 bar by 3500rpm and hold it all day long, and 1.5bar hot.

BAD POINTS:

Leaks a little oil from the crank seal i believe, easy enough to change.

2 of the 19 sump bolt threads has rounded, no real term effect.

Oil temp/level sensor doesnt work

Thats all i can really think of at the momnet, unsure of price, really but ballpark £1k.

Pictures... (in no particular order lol)

Completey stripped after being machined, installing main end bearings

Pro Seal Piston Rings, imported from USA

New Bearings..

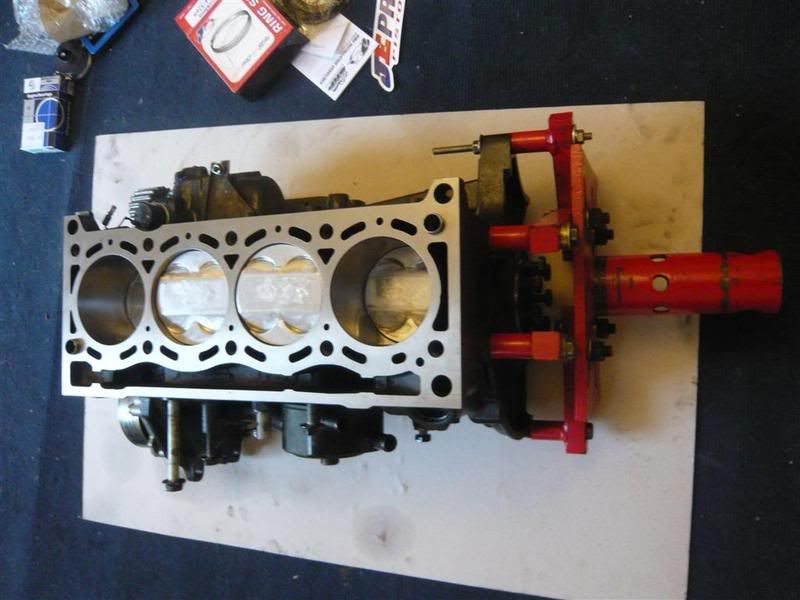

All together...

Results 1 to 10 of 16

-

02-10-2009, 01:48 #1

* BIG SPEC Forged Rebuilt F7R B/E *

-

02-10-2009, 11:29 #2

off topic but how in the hell did you manage to suck up bolts?

-

02-10-2009, 11:57 #3Forum User

- Join Date

- Oct 2006

- Location

- * Uncle Schakal * knitted by nanas since 1995 , now available with added GSOH

- Posts

- 4,467

i would pay to hear this one :D :D Originally Posted by Coops

Originally Posted by Coops

come on mr crisps ,TALK TO ME !!!

-

02-10-2009, 11:59 #4

-

02-10-2009, 12:05 #5Forum User

- Join Date

- Jan 2006

- Posts

- 1,805

They come loose Originally Posted by Coops

Originally Posted by Coops

, the ITB engine i have just bought has done 300 miles and one of the trumpets was loose due to the bolts slackening off. Its not an uncommmon problem..!

, the ITB engine i have just bought has done 300 miles and one of the trumpets was loose due to the bolts slackening off. Its not an uncommmon problem..!

Lucky i spotted it or i could have had a Laine spec motor.! :D

-

02-10-2009, 12:06 #6Forum User

- Join Date

- Oct 2006

- Location

- * Uncle Schakal * knitted by nanas since 1995 , now available with added GSOH

- Posts

- 4,467

fokkenzie

no lock nuts ? no thread lock stuff used on them ?

also are not the bolts on the outside of the trumpets ?

how the hell did they manage to get in ?

-

02-10-2009, 12:31 #7

but i thought the bolts that hold them to the bodies are on the outside of the trumpets, not the inside

-

02-10-2009, 16:30 #8

aye do the bolts not disrupt the airflow?

-

02-10-2009, 16:47 #9Forum User

- Join Date

- Jan 2006

- Posts

- 1,805

There not inside the trumpet but they come loose and rattle round in the airfilter then eventually get sucked into the trumpet then immenant disaster!!! ! Originally Posted by Coops

Originally Posted by Coops

-

02-10-2009, 16:57 #10DING DING DING, correct answer :D

Originally Posted by Evogone

Originally Posted by Evogone

See how the flange bolts are on the outside of the trumpet.

Similar Threads

-

Forged pistons low comp and forged rods

By andyrg in forum WantedReplies: 1Last Post: 14-04-2011, 13:42 -

Mit L200 White New Shape, Warrior spec, great extras / Spec

By C3 WLM in forum Cars for saleReplies: 4Last Post: 15-02-2011, 09:23 -

16v 449 Blue rebuilt f7p j reg

By midge in forum Cars for breakingReplies: 6Last Post: 26-09-2010, 15:55 -

67k mile F7R...rebuilt had

By stan in forum Items for SaleReplies: 2Last Post: 21-04-2008, 13:36 -

Engine Rebuilt

By L3WLM in forum MechanicalReplies: 1Last Post: 17-11-2005, 00:14

Reply With Quote

Reply With Quote